M/s LEP FIBRES

We M/s LEP FIBRES a leading business group, having diversified business activities for more than one decade experience in various fields of business activities. M/s LEP FIBRES set up a FRP design having largest facilities of manufacturing FRP/GRP/Composite products ie., Manhole Covers, Gully Covers, Gratings, Security Cabins, Toilet and Bio Toilet Cabins, Water and Chemical Tanks, Doors, Tables, Roofing sheets and Flower Pots etc,. in different shapes and sizes as per customer requirement and also based on its application. The Venture is established by well experienced technocrats with expertise in the field of Production, Research and Development. The Firm is floated with an intention to provide professional and cost effective FRP products. We are equipped with advance R & D Center and latest machinery as per Industry standards.

We M/s LEP FIBRES a leading business group, having diversified business activities for more than one decade experience in various fields of business activities. M/s LEP FIBRES set up a FRP design having largest facilities of manufacturing FRP/GRP/Composite products ie., Manhole Covers, Gully Covers, Gratings, Security Cabins, Toilet and Bio Toilet Cabins, Water and Chemical Tanks, Doors, Tables, Roofing sheets and Flower Pots etc,. in different shapes and sizes as per customer requirement and also based on its application. The Venture is established by well experienced technocrats with expertise in the field of Production, Research and Development. The Firm is floated with an intention to provide professional and cost effective FRP products. We are equipped with advance R & D Center and latest machinery as per Industry standards.

What is FRP?

Wood rots, Steel rusts, Alluminium dents FRP long lasts. Traditional building materials and other have their place. But Harsh and corrosive environments , Fibre Glass re-enforced polynmer (FRP) is a smart choice. Bedford structural fiberglass has the strength of steel at a fraction of the weight. It will not corrode, rot, attract insect damage or conduct electricity.

Is FRP strong?

Wood rots, Steel rusts, Alluminium dents FRP long lasts. Traditional building materials and other have their place. But Harsh and corrosive environments , Fibre Glass re-enforced polynmer (FRP) is a smart choice. Bedford structural fiberglass has the strength of steel at a fraction of the weight. It will not corrode, rot, attract insect damage or conduct electricity.

Wood rots, Steel rusts, Alluminium dents FRP long lasts. Traditional building materials and other have their place. But Harsh and corrosive environments , Fibre Glass re-enforced polynmer (FRP) is a smart choice. Bedford structural fiberglass has the strength of steel at a fraction of the weight. It will not corrode, rot, attract insect damage or conduct electricity.

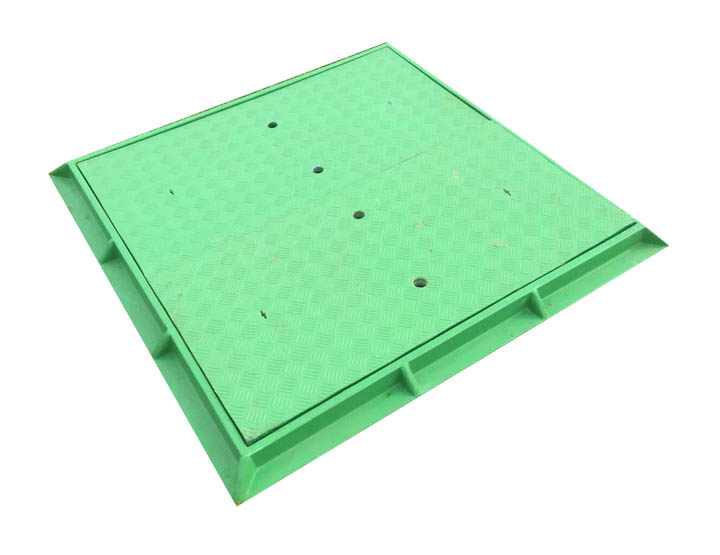

LEP FRP MANHOLE COVERS

We offer FRP manhole covers which are made of FRP high quality materials preferably used in drainage, earth pit, electrical trench covers. Sizes are available as per customer requirement.

We offer FRP manhole covers which are made of FRP high quality materials preferably used in drainage, earth pit, electrical trench covers. Sizes are available as per customer requirement.

LEP FRP WATER GULLY COVERS

We offer gully covers which are made of FRP high quality materials preferably used in drainage and Utility/Projects/Hotels/Hospital/Industrial Applications. Sizes are available as per customer requirement.

We offer gully covers which are made of FRP high quality materials preferably used in drainage and Utility/Projects/Hotels/Hospital/Industrial Applications. Sizes are available as per customer requirement.

LEP FRP GRATINGS

We offer FRP Gratings which are made of FRP high quality materials preferably used in drainage and Utility/Projects/Hotels/Hospital/Industrial Applications. Sizes are available as per customer requirement.

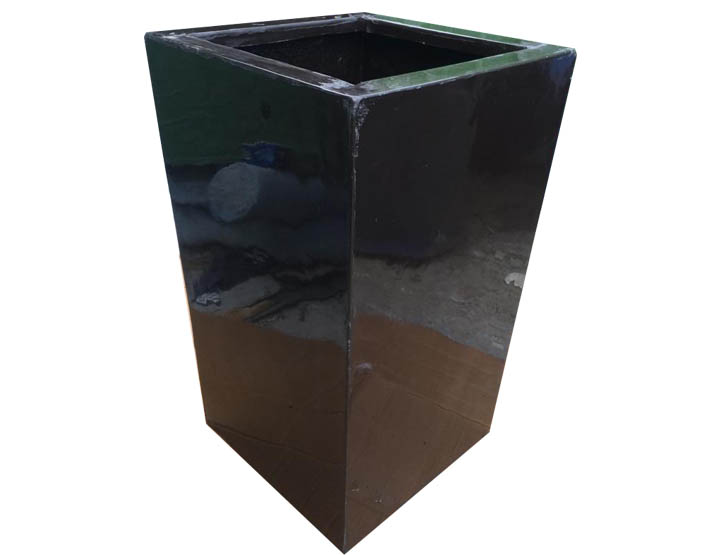

LEP FRP WARER AND CHEMICAL STORAGE TANKS

LEP FIBRES made Water and Chemical storage tanks are available in capacities ranging from 1 m3 to 400 m3. Generally tanks up to 150 m3 are made at our factory and beyond that are made at the customer’s site. We also offer complete accessories like ladders, railing, float type level indicators etc. as per the customer’s specifications and requirement.

LEP FIBRES made Water and Chemical storage tanks are available in capacities ranging from 1 m3 to 400 m3. Generally tanks up to 150 m3 are made at our factory and beyond that are made at the customer’s site. We also offer complete accessories like ladders, railing, float type level indicators etc. as per the customer’s specifications and requirement.

LEP FRP TOILET AND SECURITY CABINS

Manufactured from quality raw material our range of FRP security cabin is in high demand by our clients spread across the nation. These FRP Toilet and security cabins are known for their excellent resistance to moisture/water, ultraviolet rays, electrical shock, temperature/heat, water hammering and all chemical effects like oils, acid and various types of fumes etc. We also offer customization facilities for our clients benefit.

Manufactured from quality raw material our range of FRP security cabin is in high demand by our clients spread across the nation. These FRP Toilet and security cabins are known for their excellent resistance to moisture/water, ultraviolet rays, electrical shock, temperature/heat, water hammering and all chemical effects like oils, acid and various types of fumes etc. We also offer customization facilities for our clients benefit.

These are light weight, easy to move and install and are resistant to extreme weather.

We can offer these in different sizes and shapes to meet the exact demands of our clients.

LEP FRP SHEETS

LEP FIBRES manufactures FRP Sheets in custom colors, shapes & sizes as per client’s requirement.

LEP FRP DOORS

Our range of FRP doors are known to provide the door durability, strength and protection from corrosion, leakages, rusting, rotting problems.

LEP FRP BIO DIGESTER TANKS

Defence Research and Development Organisation developed the technology of bacterial inoculums for sewage treatment under diverse geo-climatic conditions for which BIO-TANK is required. For the purpose of the above LEP FIBRES manufactures FRP Bio Digester tanks.

Defence Research and Development Organisation developed the technology of bacterial inoculums for sewage treatment under diverse geo-climatic conditions for which BIO-TANK is required. For the purpose of the above LEP FIBRES manufactures FRP Bio Digester tanks.

LEP FRP LAYER COATING/ FRP LINING

LEP FIBRES also repairs rusted and damaged steel pipelines, steel storage tanks, steel cooling towers and damaged roof tops by providing FRP Layer coating.

ADVANTAGES OF FIBRE-REINFORCED POLYMERS

Long Life: Our fiberglass products are built to last. Fibreglass has high resistance to fatigue and has shown excellent durability over the last 50 years..

Long Life: Our fiberglass products are built to last. Fibreglass has high resistance to fatigue and has shown excellent durability over the last 50 years..

Low Maintenance: Once installed, fibreglass products require minimal maintenance.

Low Weight: Even the cheapest fibreglass is much less dense and therefore lighter than the equivalent volume of steel or concrete.

Mechanical Strength: Fibreglass is so strong and stiff for its weight, it can out-perform most other materials including steel, aluminum and timber. The strength and stiffness per weight of these exotic materials exceeds that of all known materials.

High Impact Strength: In contrast to most metals, fibreglass does not change shape even when it is ruptured.

Durable Custom Colours: Fibreglass can be coloured, shiny or dull. We can even add patterns if you wish, your production costs are reduced as our gelcoated products don’t need further painting or finishing. With care, the gelcoat finish on our automotive parts can last for up to 20 years.

Chemical Resistance: Fibreglass is minimally reactive, making it ideal as a protective covering for surfaces where chemical spillages might occur. It is useful in the construction of tanks, hoods, covers, pipes, ducts and other structures in the paper, chemical, water treatment and petroleum industries.

Chemical Resistance: Fibreglass is minimally reactive, making it ideal as a protective covering for surfaces where chemical spillages might occur. It is useful in the construction of tanks, hoods, covers, pipes, ducts and other structures in the paper, chemical, water treatment and petroleum industries.

Corrosion Resistance: Unlike metal, fibreglass does not rust away and it can be used to make long-lasting structures.

Free from Theft: The FRP material is free from theft as the material is non reprocessable.

Electrically Insulating: For those working in the power industry, materials such as fibreglass which do not conduct electricity are essential for safety. However, if required, we can adapt our fibreglass to become electrically conductive.

Thermally Insulating: Fibreglass is not only long lasting but maintains its temperature, thus reducing heating and cooling costs. The fiberglass surface remains comfortable to touch, being neither hot nor cold.

Fire Resistance: By the addition of special additives, fiberglass can be made fire resistant to meet most fire codes. The resins used conform to BS476 or ASTM-E-84.

And also low Thermal Expansion: Anti-Magnetic, No Sparks: Infinite Potential: Resilience: Formability: Weatherproof